2. Inspect the journals for wear, scratches, corrosion, and cracks.

19.3 Run a copper coin along the neck of the shaft - if there is a trace of a coin, the surface of the neck must be turned

3. Run a copper coin along each of the necks several times. If the coin leaves a mark, then the surface of the neck is very rough and needs to be turned (19.3).

4. Remove nicks around the oil holes.

5. Inspect the crankshaft for cracks or other damage. Contact a specialist to find hidden cracks.

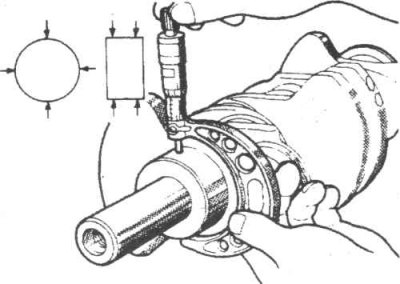

19.6 Measure the diameter of each of the journals in several places to check if the journal has acquired a conical or oval shape. The cylinder needs to be bored and new pistons and rings installed

6. Using a micrometer, measure the diameter of the crankshaft journals (19.6) in several places along the circumference of the neck and along its length.

7. If the crankshaft journals are damaged, have become conical or oval, contact a crankshaft processing specialist.

8. Check the crankshaft seal journals for wear and damage. If a groove is worn on the neck or it is scratched, then the new stuffing box will not be tight. Contact a specialist to install a smaller oil seal or replace the crankshaft.

9. Inspect the bearing shells.