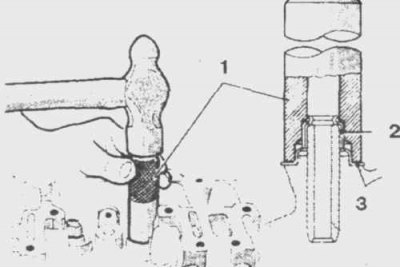

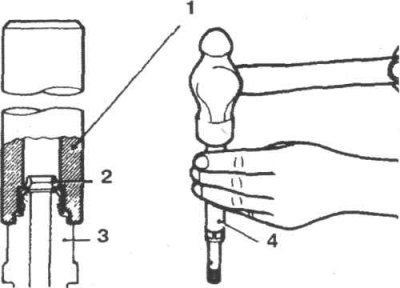

12.2 A deep sleeve or special tool is required to install the valve seal

1. Special tool; 2. Seal; 3. Spring seat

2. Install new seals on the intake valve guides (12.2).

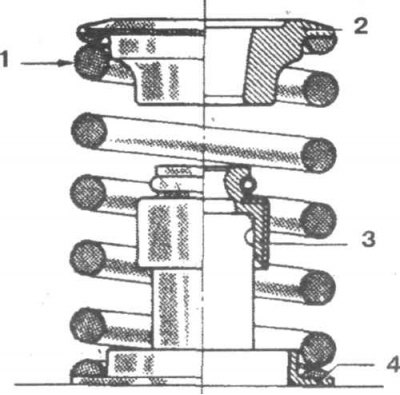

12.3 If enamelled valve springs were installed in the head, install them with the enamelled ends away from the head as shown in the figure

1. Enamelled spring end; 2. Plate; 3. Seal; 4. Spring seat

3. Lubricate and install the first valve. Install the spring seat on the guide bushing and install the spring and the plate (12.3).

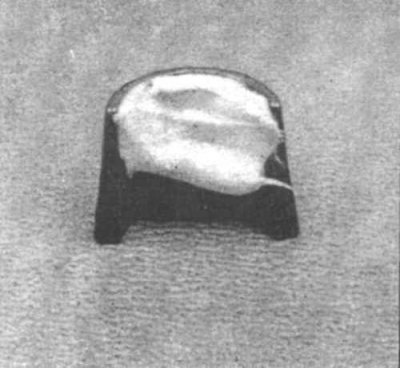

12.4 Lubricate crutches with grease before installation

4. Compress the spring and install the crackers, after lubricating them (12.4).

5. Install other valves in the same way.

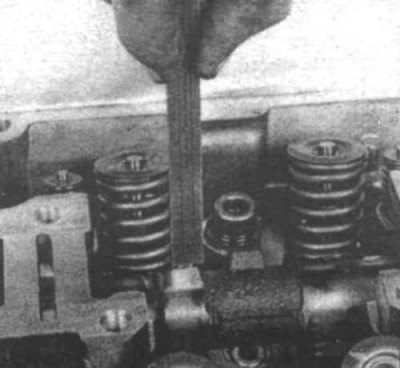

12.6 Check the height of the valve spring

6. Check valve height. It is measured from the top of the valve spring seat to the bottom of the poppet (12.6). If the height is too high, install washers under the spring.

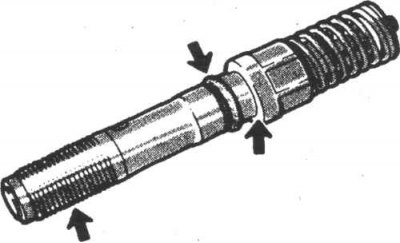

12.7 A special tool is used to replace the dilute mixture inlet valve seal

1.MD998308; 2. Seal; 3. Valve body; 4.MD998308

7. Using tool N MD998308, install the seal on the dilute mixture inlet valve stem (12.7).

8. Lubricate the valve stem and reinstall it.

9. Compress the spring with tool N MD998309 and install it together with the poppet. Install croutons.

12.10 Use new o-rings when installing dilute mixture inlet valves. Lubricate the rings, threads and seat with engine oil (indicated by arrows)

10. Install a new o-ring on the valve and lubricate it with engine oil (12.10). Also lubricate the threads and seat.

11. Install the dilute mixture inlet valves and tighten to the correct torque.

12. Lubricate the rocker arms, camshaft and rocker shafts with molybdenum grease, then reinstall the camshaft, rocker arms and rocker shafts.