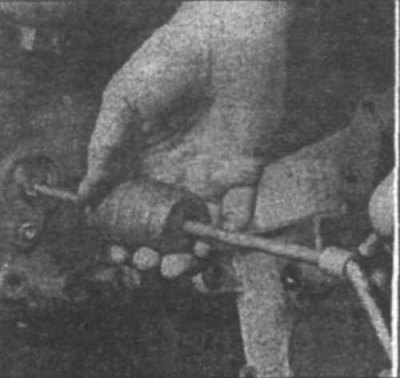

15.1 Use a puller to remove the plugs

1. Drill holes in the plugs and remove them with a puller (15.1).

2. Remove traces of the old gasket and sealant from the surface of the cylinder block.

3. Remove covers of radical bearings and loose leaves.

4. Remove all plugs from the cylinder block.

5. If the engine is very dirty, ask a professional to clean it.

6. After cleaning the block, clean the oil passages and wash them with warm water. Dry the cylinder block and lubricate with anti-corrosion oil.

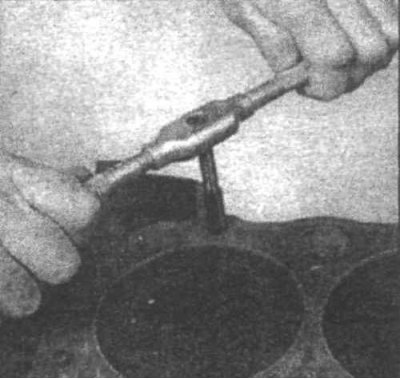

15.7 Clean the threaded holes in the cylinder block

7. Clean the threaded holes in the cylinder block with a sword, then blow them out with compressed air (15.7).

8. Reinstall the main bearing caps and lightly tighten the mounting bolts.

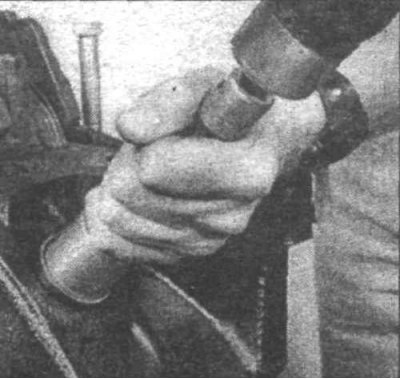

15.9 Use the large head and extension to install new plugs

9. Lubricate the plugs with Permatex N2 sealant and install them on the cylinder block (15.9).

10. Lubricate with sealant (such as Permatex N2 or Teflon pipe sealant) new oil channel plugs and screw them into the holes in the cylinder block.

11. If you will not continue to assemble the engine, cover it with a plastic bag