Fuel pump - check

Models with a carburetor engine

Attention! Be careful when working with gasoline!

1. Check fuel lines for leaks.

2. If no leaks are found, check the fuel pump by first disconnecting the negative battery terminal wire.

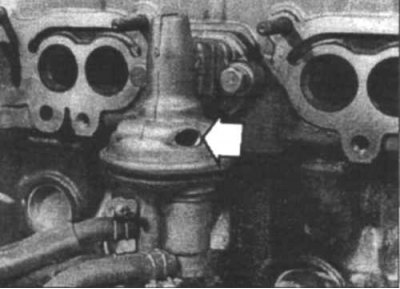

Checking the vent

3.3 Check the fuel pump vent (indicated by an arrow) - if oil or gasoline flows out of it, replace the fuel pump

3. Check if fuel or oil is leaking from the vent (3.3). If there is a leak, replace the fuel pump.

Checking the operation of the pump

4. Disconnect the fuel supply pipe from the carburetor and lower the end of the pipe into a suitable container.

Connect the negative battery cable. Disconnect the wires from the primary terminals of the ignition coil.

5. Crank the engine with the starter for about 10 seconds. If fuel is ejected in rhythmic portions, then the pump is working. If not, replace it.

Inlet valve check

6. Disconnect the fuel supply hose from the pump. Connect a vacuum gauge to the pump port. Turn the engine over with the starter.

7. The pressure gauge should register the presence of a constant vacuum. If the pressure jumps, then the intake valve does not provide sufficient sealing and the fuel pump must be replaced.

Models with multiport fuel injection

8. Release pressure from the supply system.

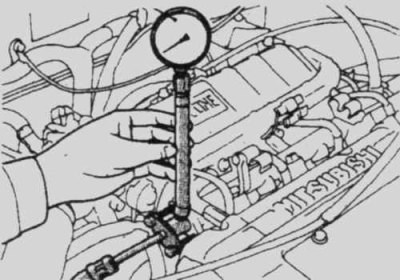

3.9 On models with multi-point fuel injection, use a special adapter (MD 998742 or equivalent) to install a pressure sensor

9. Disconnect the fuel supply pipe from the fuel manifold and connect the pressure sensor (3.9).

10. Start the engine and compare the pressure shown on the gauge with the pressure shown in the specifications section.

11. Disconnect the vacuum hose from the pressure regulator and close the end of the hose. Read the pressure gauge.

12. Rotate the engine crankshaft two or three times. Start the engine and read the pressure gauge.

13. Lightly pinch the pressure regulator return hose and check for pressure.

14. If the fuel pressure was low in both tests, then the fuel filter or fuel supply pipe is clogged or the fuel pump is faulty.

15. If the pressure was high when the pressure regulator was connected, then the regulator is faulty or it does not receive vacuum.

16. If the pressure was low when the regulator was connected, and normal after the regulator was disconnected, then the pressure regulator is faulty.

Models with two-point fuel injection

17. Release pressure from the supply system.

3.18 On models with two-point fuel injection, use a special adapter (MD 998742 or equivalent) to install a pressure sensor

18. Disconnect the fuel supply pipe from the throttle block and connect the pressure sensor (3.18).

19. Start the engine and compare the pressure shown by the gauge with the pressure indicated in the specifications section.

20. If the pressure is low, check if the fuel filter is clogged, if the pressure regulator is out of order, if there is a leak in the fuel supply pipe and if the fuel pump is working.

21. For a more detailed diagnosis, contact a specialist.