Removing

1. Set piston N1 to top dead center.

2. Disconnect the wire from the negative terminal of the battery.

3. Remove the valve cover.

4. Remove the ignition distributor (for SOHC engines) or crankshaft angle sensor (DOHC engines).

SOHC engines

5. Drain the coolant from the cooling system and the upper radiator hose from the thermostat.

6. Remove the fuel pump.

7. Remove the timing belt and sprocket (ki) camshaft (ov)

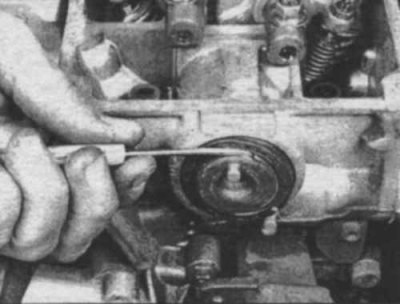

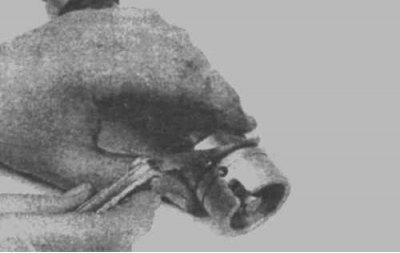

9.8 Carefully remove the oil seal, being careful not to scratch the metal surfaces (1.5 l)

8. Wrap tape around the tip of the screwdriver. Carefully remove the camshaft oil seal from the groove using a screwdriver (9.8).

9. Remove an axis of yokes together with yokes.

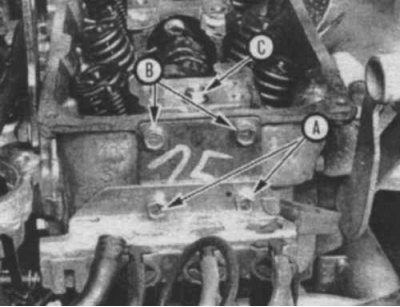

9.10 On 1.5L engines, unscrew the bottom bolts (A) and remove the bracket, then unscrew the top bolts (IN) and retaining ring bolt (WITH)

10. On 1.5L engines, remove the rear cylinder head cover and unscrew the camshaft thrust ring bolts (9.10).

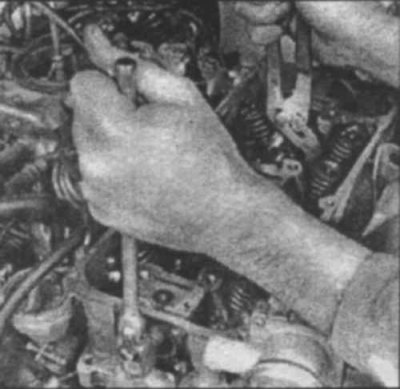

9.11 On 1.5 liter engines, clamp the camshaft between the third and fourth cams and unscrew the shaft thrust ring bolt

11. Stop the camshaft and unscrew the bolt of the camshaft thrust cover (9.11).

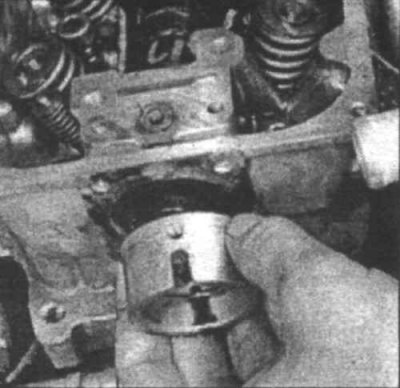

9.12 On 1.5 liter engines, remove the thrust ring from the cylinder head.

12. Get an emphasis from the block of cylinders (9.12).

9.13 Remove the camshaft from the cylinder head

13. For better access, unscrew the windshield washer reservoir and move it to the side. Remove the camshaft from the cylinder head (9.13).

DOHC engines

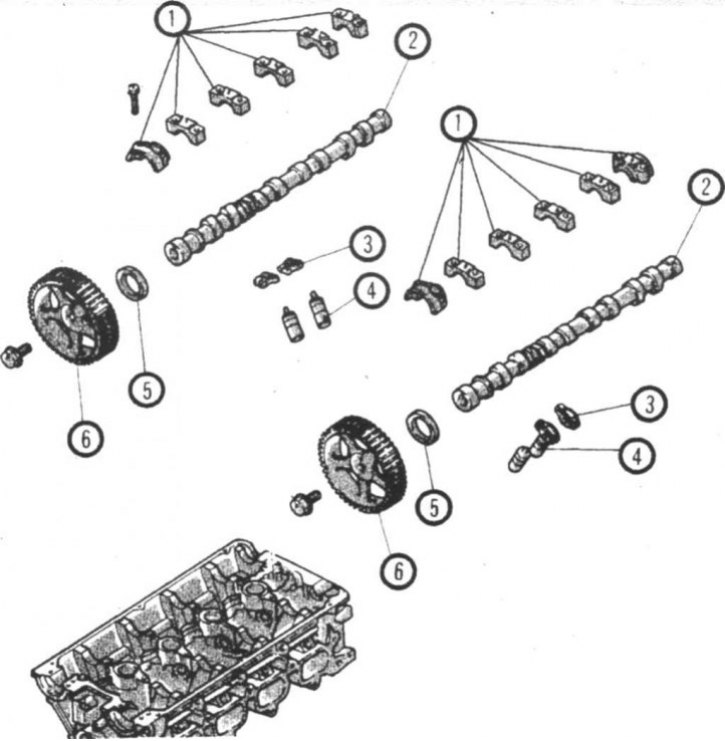

9.14 Camshafts for DOHC engines

1. Bearing caps; 2. Camshaft; 3. Rocker arms; 4. Rocker lifts; 5. Camshaft oil seal; 6. Camshaft sprocket

14. Remove the camshaft bearing caps. Carefully remove the camshafts from the cylinder block (9.14).

Examination

15. Thoroughly clean the camshafts, the back cover and the surfaces on which the gaskets are installed.

16. Inspect the camshafts, drive gear, and cam surfaces for wear and damage. Inspect bearing surfaces for damage.

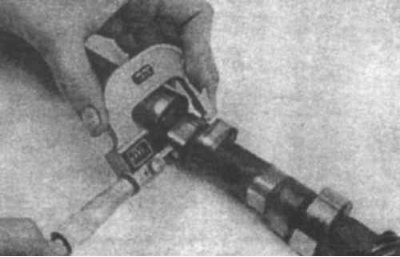

9.17 Measure the height of the cams

17. Measure the height of the cams (9.17) and compare them with the specification data.

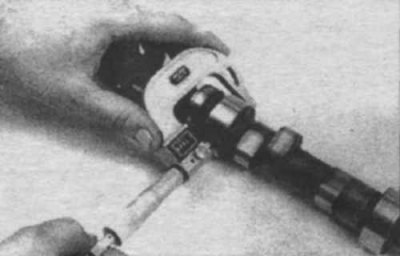

9.19 Measure bearing diameters

18. Measure bearing diameters (9.19), and then measure the inner diameters of the bearing shells in the cylinder head. Subtract the bearing diameter from the bushing diameter to get the lubrication gap. Compare the value obtained with the value given in the Specifications.

19. Replace the camshaft if it fails one of the above checks. If the cams are worn out, replace the camshaft together with the rocker arms. If the bearing shells are damaged or worn, the cylinder head may need to be replaced.

9.20 Use a feeler gauge to measure the end play (1.5L engines)

20. In engines of 1.5 liters, install the thrust ring on the camshaft and tighten the bolt. Check the axial clearance of the shaft (9.20).

21. If the end play is too large, check how worn the other end of the shaft is. If wear is excessive, replace the shaft.

Installation

23. Lightly coat bearings and shaft bearings with engine oil.

24. Carefully install the shaft into the cylinder head.

25. On SOHC engines, install thrust washer. Secure the retaining ring with the bolt. Install the rear cover with a new gasket and tighten the bolts to the correct torque.

26. On DOHC engines, install the shaft bearing caps. Tighten the cover bolts to the required tightening torque.

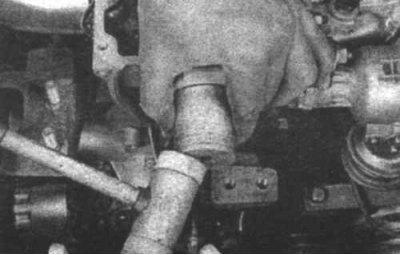

9.27 Install the gland (1.5L engines)

27. Lubricate the shaft seal with engine oil and install it in place (9.27).

28. Establish sprockets of camshafts and tighten bolts to the demanded moments of an inhaling.

29. Install the timing belt.

30. On SOHC engines, install the rocker and rocker shafts.

31. Adjust valve clearances.

32. Install the remaining parts.

33. Start and warm up the engine.

34. Re-adjust the valves.

35. Install the valve cover and check the engine for oil leaks.