Attention! Do not attempt to rotate the crankshaft with the bolt located on the crankshaft sprocket, do not rotate the crankshaft counterclockwise, and do not rotate the crankshaft after you have removed the timing belt.

1. Set piston N1 to top dead center.

2. Disconnect the wire from the negative terminal of the battery.

3. Remove the air filter and related hoses.

4. Put the car on the handbrake and block the rear wheels. Jack up the front of the car and secure it to jack stands under the axles.

5. Remove the left engine mount.

Attention! The engine must rest on a stand mounted under the oil pan.

SOHC Engines Removal

6. Loosen the water pump pulley bolts and remove the drive belts.

7. Unscrew and remove the water pump pulley.

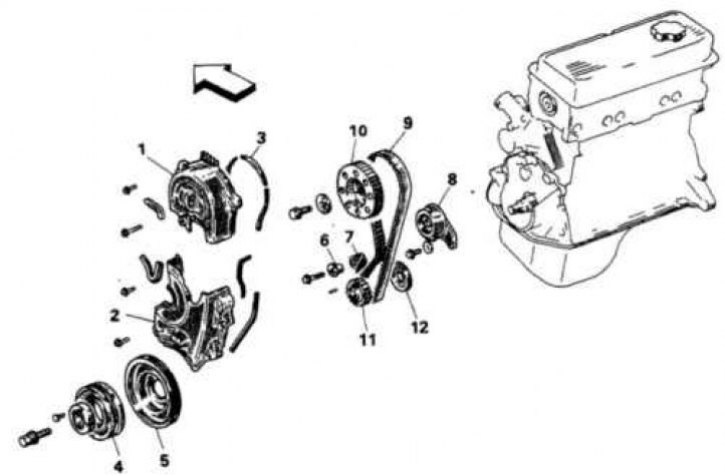

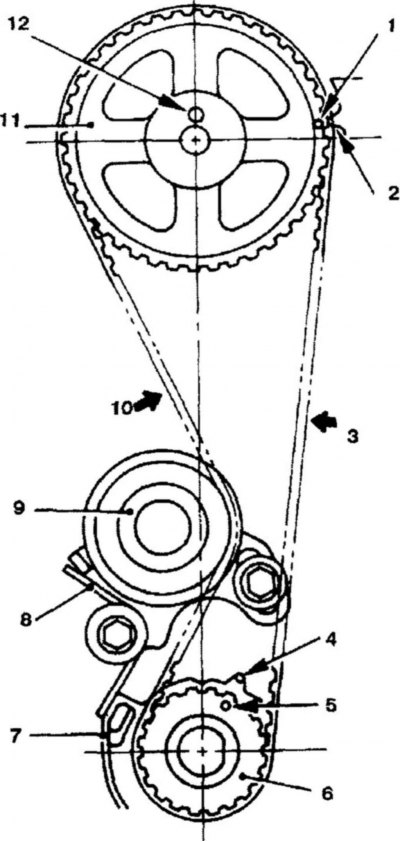

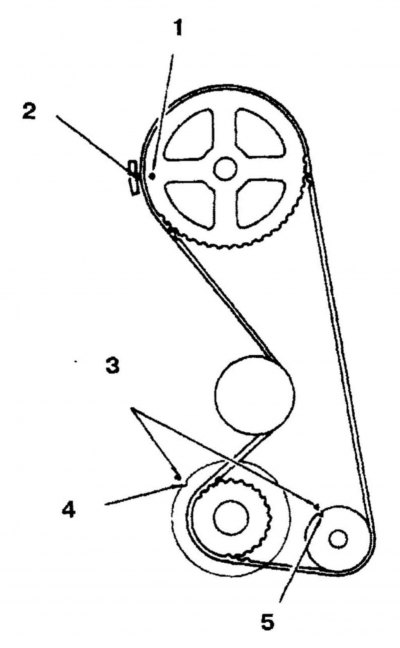

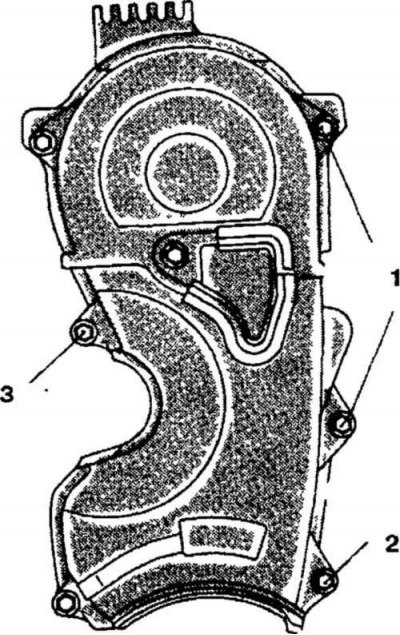

7.8a Timing belt for 1.5 liter engine

1. Top cover; 2. Bottom cover; 3. Gasket; 4. Damper pulley; 5. Crankshaft pulley; 6. Tensioner bushing; 7. Tensioner spring; 8. Tensioner; 9. Gas distribution belt; 10. Camshaft sprocket; 11. Crankshaft sprocket; 12. Belt guide

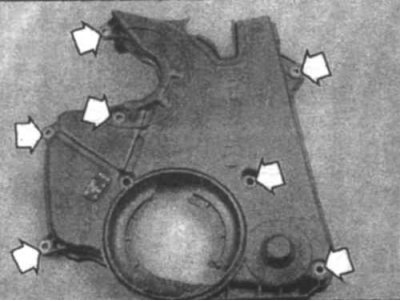

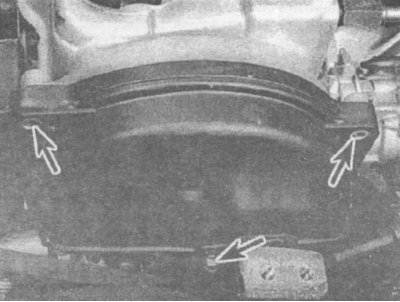

8. Unscrew the bolts securing the top cover of the timing belt (7.8a, 7.8b, 7.8c, 7.8d, 7.8e) and remove the cover. Unscrew the screws securing the bottom cover and remove it.

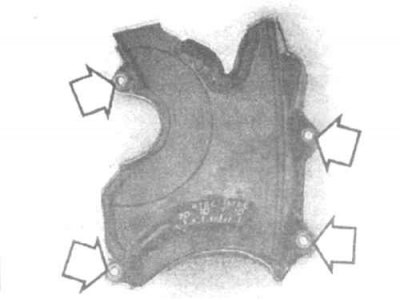

7.8d Arrows indicate the location of the bolts of the lower cover of the timing belt (2.0 l)

7.8b Engine timing belt with a capacity of 1.8 l, 2.0 l, 2.4 l

1. Bolt; 2. Crankshaft pulley; 3. Flange bolt; 4. Flange bolt; 5. Top front cover; 6. Gasket; 7. Access hole cover; 8. Gasket; 9. Gasket; 10. Gas distribution belt; 11. Flange bolt; 12. Washer; 13. Nut; 14. Sleeve; 15. Tensioner spring; 16. Tensioner; 17. Sleeve; 18. Bolt; 19. Camshaft sprocket; 20. Nut; 21. Oil pump sprocket; 22. Crankshaft sprocket bolt; 23. Washer; 24. Crankshaft sprocket; 25. Spring pin; 26. Flange; 27. Bolt; 28. The back of the tensioner; 29. Silent shaft belt; 30. Flange bolt; 31. Washer; 32. Silent shaft sprocket; 33. Sleeve; 34. Rear crankshaft sprocket; 35. Key

7.8v The top cover of the timing belt is fixed with three bolts (indicated by arrows) (2.0 l)

7.8g The arrows indicate the location of the bolts of the lower cover of the timing belt (1.5 l)

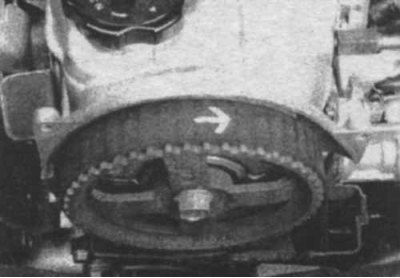

7.9 If you are going to reuse the timing belt, draw an arrow on it indicating the direction of rotation (clockwise)

9. If you are going to use the timing belt again, draw an arrow on it indicating the direction of rotation (clockwise) (7.9).

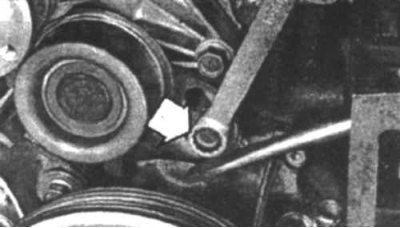

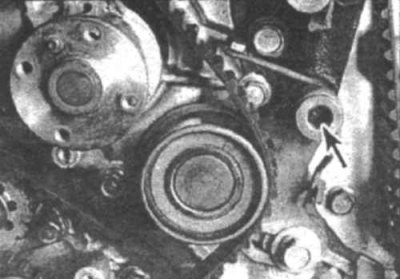

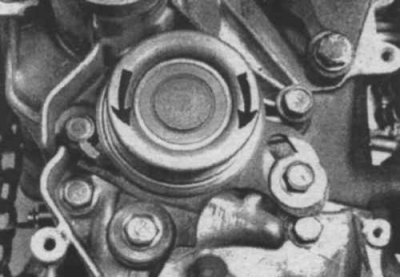

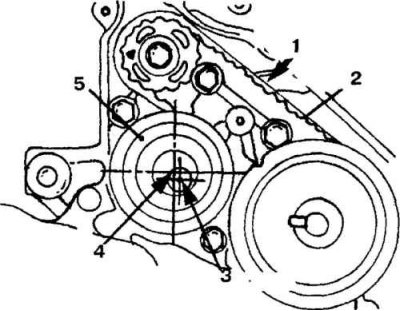

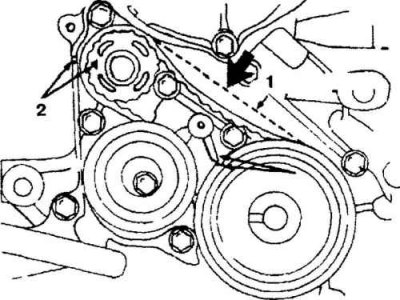

7.10a Loosen tensioner bolt (indicated by an arrow) and slide the tensioner towards the water pump (1.5 l)

7.10v Location of timing marks on 16-valve SOHC engines. The automatic tensioner is fixed with two bolts, the tensioner plunger presses on the tensioner lever, and the tat, in turn, presses the tensioner pulley against the belt

1. Camshaft sprocket timing marks; 2. Oil pump sprocket timing marks; 3. Crankshaft sprocket; 4. Timing marks of the crankshaft sprocket; 5. Automatic tensioner

7.10b Tensioner bolt (indicated by an arrow) (2.0 l)

10. In 8-cylinder engines, loosen the adjusting bolt and slide the timing belt tensioner all the way towards the water pump (7.10a, 7.10b, 7.10c). Temporarily fix the tensioner in this position by tightening the bolt. On 16 valve engines, unscrew and remove the tensioner, loosen the tensioner arm bolt so that the arm hangs freely (7.10v).

7.11 Unscrew the central bolt of the crankshaft pulley (1.5 l)

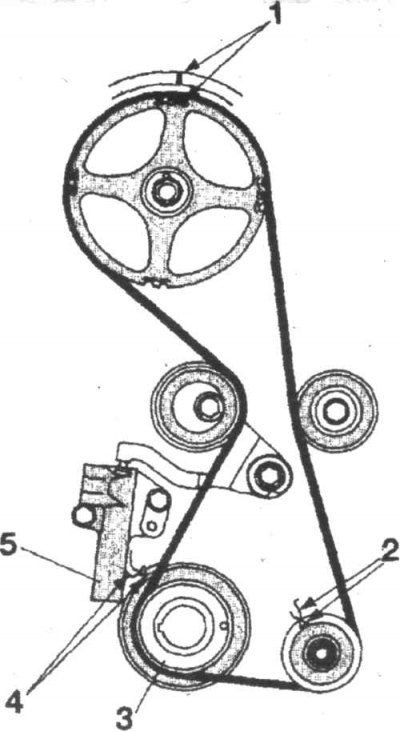

11. Remove the large center bolt from the crankshaft pulley (7.11).

Attention! On some models, the pulley is secured with four bolts.

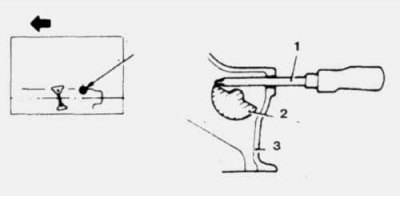

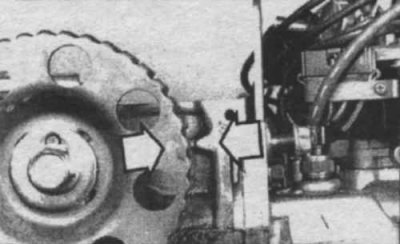

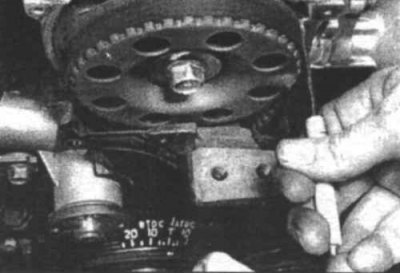

7.12 Insert a screwdriver between the teeth of the flywheel to prevent the crankshaft from rotating.

12. If you cannot unscrew the bolt due to the fact that your key is slipping, lock the crankshaft by inserting a screwdriver between the teeth of the flywheel (7.12). In order to do this, you will have to first remove the flywheel cover.

13. Make sure the tensioner bolts are loose and remove the timing belt.

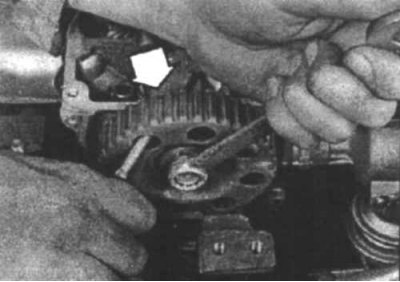

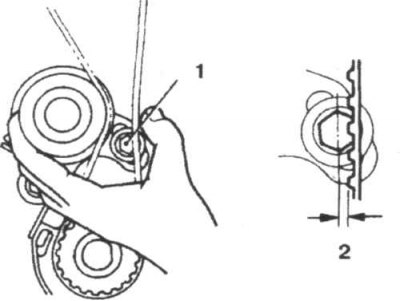

7.14 To prevent the sprocket from rotating while you unscrew the bolt, lock it by inserting a screwdriver into one of the holes. The tip of the screwdriver should rest against the gasket (arrow) not to damage the cylinder head (1.5 l)

14. If you want to remove the camshaft, unscrew the camshaft sprocket bolt and remove the sprocket. To prevent the sprocket from rotating while you unscrew the bolt, lock it by inserting a screwdriver into one of the holes (7.14). Remove the oil pump sprocket as well and check the pump seal for damage or leakage.

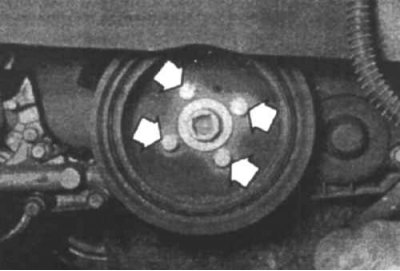

7.15a Unscrew the bolts of the crankshaft pulley (indicated by arrows) (2.0 l)

7.15b When removing the guide flange of the timing belt, remember its correct location (1.5 l)

15. If you want to replace the front crankshaft oil seal, unscrew the four bolts of the crankshaft pulley and remove the pulley (7.15a). Remove the crankshaft sprocket and timing belt guide flange (7.15b), behind the asterisk (remember the correct location of the flange).

7.16 Use a screwdriver to lock the silent shaft

1. Screwdriver (8 mm); 2. Silent shaft; 3. Cylinder block

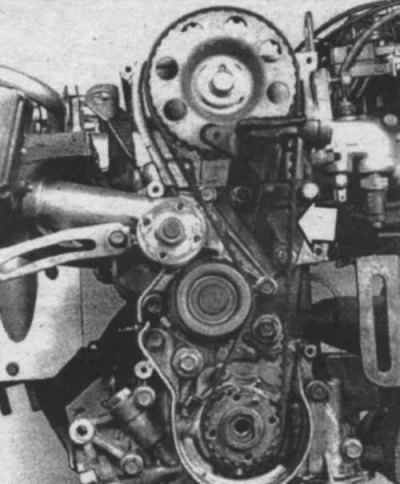

16. On 1.8L, 2.0L, 2.4L engines, remove the plug on the left side of the cylinder block and insert a screwdriver to lock the silent shaft (7.16).

17. Loosen the bolt securing the silent shaft sprocket.

18. Loosen the tensioner and remove the silent shaft belt (7.8v).

Examination

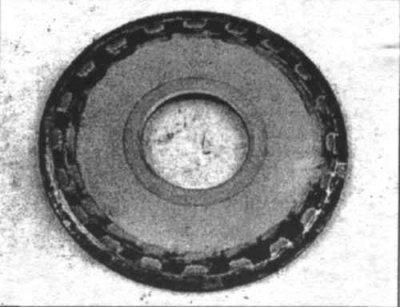

7.19 Rotate the tensioner pulley by hand and move it from side to side to check if the pulley is binding or if there is excessive play (1.5 l).

19. Rotate the tensioner pulley by hand and move it from side to side to check if the pulley is binding or if there is excessive play (7.19). Inspect sprockets for signs of wear or damage. Replace damaged parts if necessary.

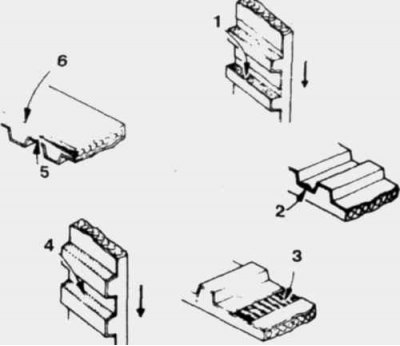

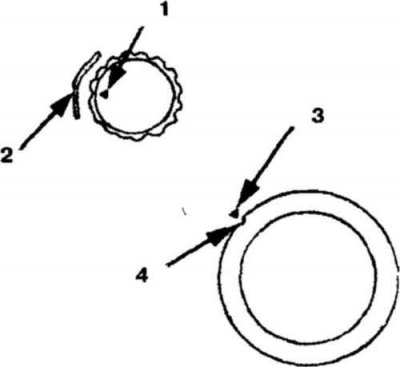

7.20 Carefully inspect the timing belt for damage

1. Rubber protrudes; 2. detachment; 3. There is no tooth, and the fibers protrude; 4. Wear on the working side; 5. Strong wear; 6. Rounded side of the belt

20. Inspect the timing belt (7.20) for cracks, wear, delamination, missing teeth and oil contamination. Replace the belt if you are in doubt about its suitability.

Installation

21. Reinstall the timing belt sprockets if you removed them. Before putting on the crankshaft sprocket, put on the guide flange (7.8b, 7.8c, 7.8d).

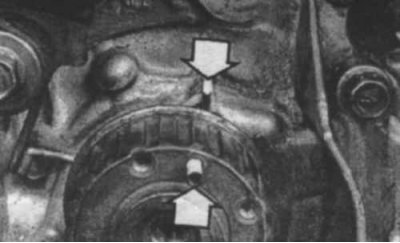

7.22a Align the pin on the crankshaft sprocket with the mark on the oil pump (indicated by arrows) (1.5 l).

22. Align the timing marks on the camshaft, crankshaft and oil pump sprockets with the marks on the cylinder head and cylinder block (7.22a, 7.22b, 7.22c, 7.10c).

7.22v Timing marks on crankshaft and camshaft sprockets (1.5 l).

1. Synchronization mark (camshaft sprocket); 2. Synchronization mark (cylinder head); 3. Tightened side of the belt; 4. Synchronization mark (cylinder block); 5. Synchronization mark (crankshaft sprocket); 6. Crankshaft sprocket 7 Cylinder block; 8. Tensioner spring; 9. Belt tensioner; 10. Loose side of the belt; 11. Camshaft sprocket; 12. Pin

7.22b Align the triangular mark on the camshaft sprocket with the mark on the cylinder head (indicated by arrows) (1.5 l).

7.22g Timing marks on crankshaft and camshaft sprockets (1.6L engine).

1. Camshaft sprocket; 2. Timing mark on the timing belt cover; 3. Synchronization mark; 4. Tightened side of the belt; 5. Tensioner spring; 6. Oil pump sprocket; 7. Crankshaft sprocket; 8. Synchronization mark; 9. Synchronization mark on the cylinder block; 10. Belt tensioner; 11. Loose side of the belt

7.22d Synchronization marks on the sprockets of the crankshaft and camshaft (1.8L, 2.0L, 2.4L engine).

1. Synchronization mark (hole in star); 2. Synchronization mark (on the cylinder head); 3. Synchronization marks (on the cylinder block) 4 Synchronization mark (notch in the flange); 5. Synchronization mark (hole in star)

7.23 Align the timing marks before installing the rear belt (1.8L, 2.0L, 2.4L engines)

1. Synchronization mark (on an asterisk); 2. Synchronization mark (slot in the cylinder block); 3. Synchronization mark (on the cylinder block); 4. Synchronization mark (hole in star)

23. On 1.8L, 2.0L, 2.4L engines, install the rear belt. Align the timing marks on each of the sprockets with the marks on the cylinder block (7.23)

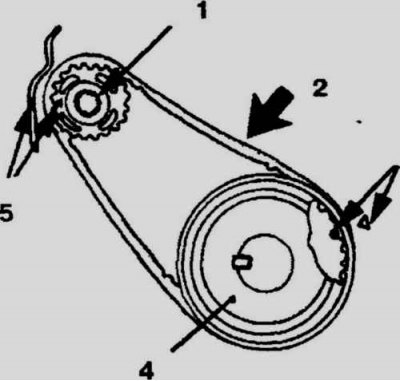

7.24 Installing the timing belt.

1. Tightened side of the belt; 2. Back belt; 3. Central belt; 4. Center pulley tensioner; 5. Rear belt tensioner

24. After you have installed the rear belt, make sure that the tensioned side of the belt does not sag (7.24).

25. Check that the center of the rear belt tensioner sprocket is located on the left side of the set bolt (7.24).

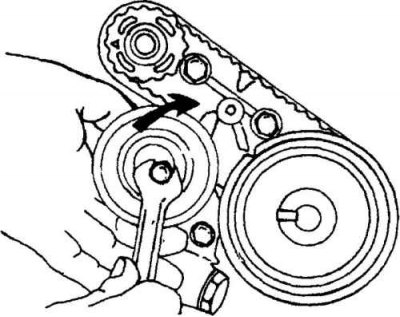

7.25a Turn the tensioner clockwise and up to tension the belt

7.25b Press the middle of the belt to check its deflection

1. Synchronization marks; 2. Synchronization marks

Raise the tensioner with your finger to tension the belt (7.25a, 7.25b) and tighten the tensioner bolt and the silent shaft bolt to the tightening torques specified in the specifications. The deflection of the belt should be in the range of 5.0-7.0 mm.

7.26 Installing the timing belt (1.5l)

26. Put the timing belt on the crankshaft sprocket. Pulling the back of the belt, put it on the camshaft sprocket (7.26).

27. On 8 valve engines, loosen the tensioner lock bolt to tighten the belt. Tighten the bolt.

28. Install the crankshaft pulley by carefully aligning the dowel pin with the small hole in the pulley. Insert pulley bolts (fixing bolts and central bolt) and tighten them to the required tightening torques.

7.29 Alignment of the timing marks of the camshaft sprocket

29. Rotate the crankshaft two full turns. Check synchronization marks alignment (7.29). If the marks are not aligned, loosen the tensioner, remove the belt from the camshaft sprocket, align the marks, reinstall the belt and check the marks again.

7.30a The belt is correctly tensioned if, when pressed, it deviates by one fourth of the width of the head of the adjusting bolt (1.5L engines)

1. Tensioner bolt; 2. One fourth of the width of the bolt head

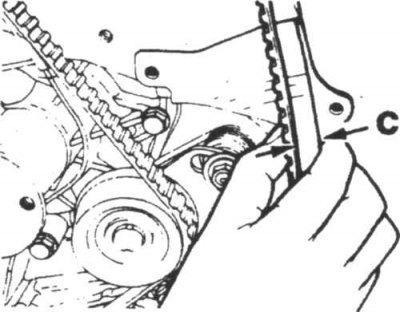

7.30b Press the belt against the cover and measure the distance between the belt and line C

30. On 1.5 liter engines, check the belt tension by pushing it in. The belt should deflect no more than one-fourth the width of the head of the adjusting bolt (7.30a). If the belt is too tight or too loose, loosen the tensioner bolts and adjust the belt tension. In engines with a volume of 1.8 l, 2.0 l (8 valve), 2.4L and 1.6L push the strap to the cap (7.30b) and measure the distance between the belt and line C. The distance should be approximately 14mm for 1.8L, 2.0L engines (8 valve), 2.4 l. In 1.6 liter engines, the distance should be 6 mm.

31. Tighten the tensioner bolts to the correct torque.

7.32 Insert the bolts into the timing belt cover (1.5L engines)

Thread Diameter x Length (mm) 1.6x18 2.6x38 3.6x18

32. Replace the remaining parts. Please note that the timing belt cover bolts are of different lengths (7.32).

33. Start the engine and road test the vehicle.

DOHC engines

Attention! Mitsubishi DOHC 4G32 and 4G61 engines are the same, except that in the engine installed in the Colt, Lancer, Mirage (4G61 - 1989-1990) no silent shaft.

Removing

34. Carry out the operations described in paragraphs 1-5.

35. Remove the power steering hose clamp and air conditioner hose clamp.

36. Remove drive belts and tensioner pulley bracket.

37 Remove the water pump pulley.

38. Remove the crankshaft pulley. Unscrew the bolts from the crankshaft pulley (7.11) If you cannot unscrew the bolt because your key is slipping, lock the crankshaft by inserting a screwdriver between the teeth of the flywheel (7.12).

39. Unscrew the fixing bolts of the upper and lower timing belt covers and remove the covers.

40. Remove the valve cover.

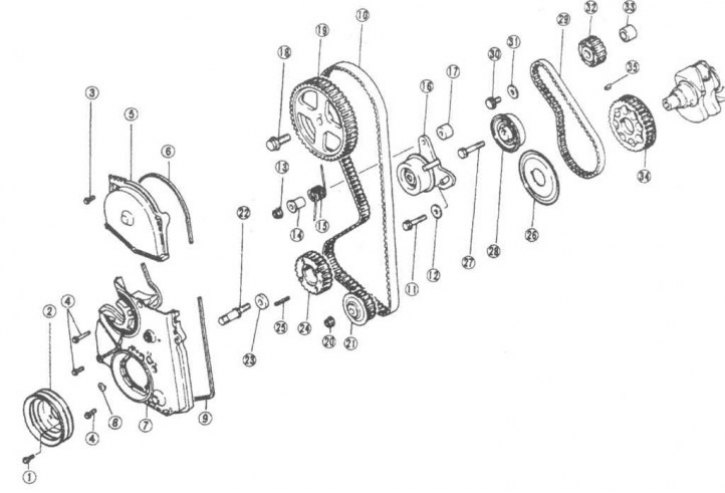

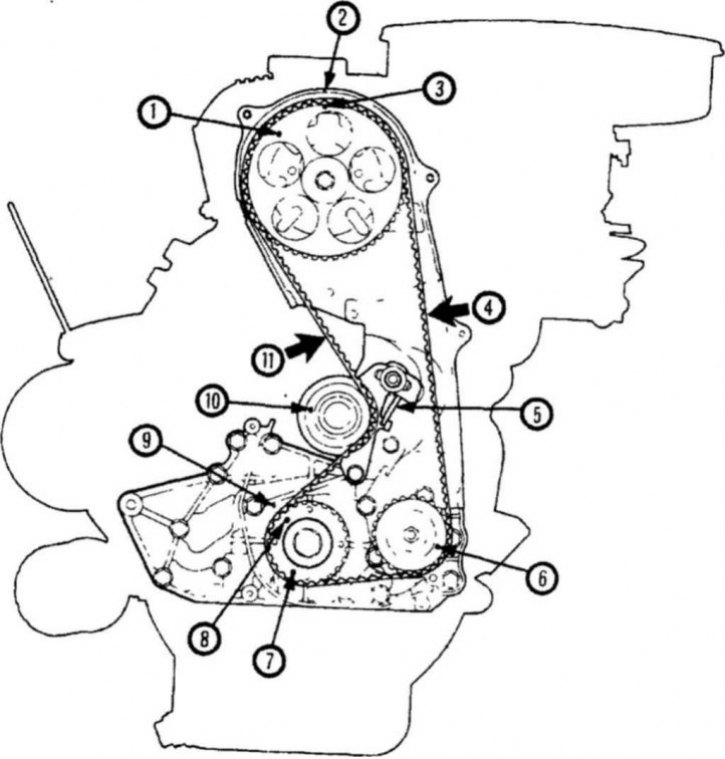

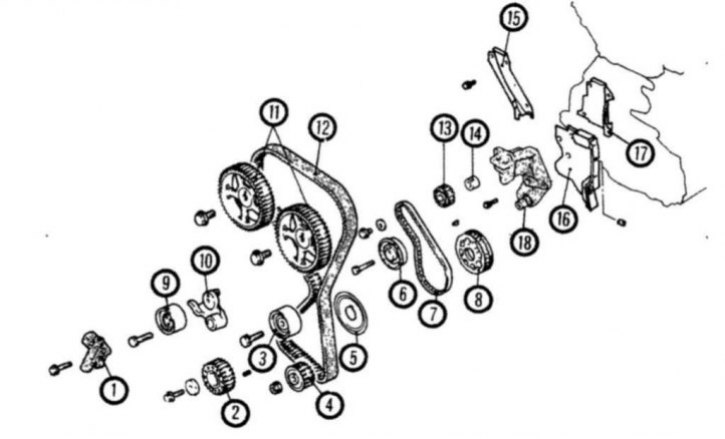

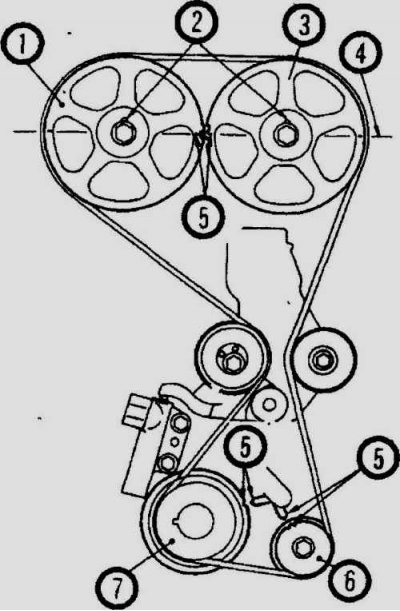

7.41 Timing belts and sprockets for DOHC engines (4G32 engine shown)

1. Automatic tensioner; 2. Crankshaft sprocket; 3. Intermediate pulley; 4. Oil pump sprocket; 5. Flange; 6. Rear tensioner; 7. Rear belt; 8. Crankshaft sprocket rear; 9. Tensioner pulley; 10. Tensioner lever; 11. Camshaft sprocket; 12. Gas distribution belt; 13. Silent shaft sprocket; 14. Sleeve; 15. Rear right timing belt cover; 16. Rear left (lower) belt cover; 17. Rear left (upper) belt cover; 18. Engine support bracket

41. Remove auto tensioner (7.41).

42. If you are going to reuse the belt, make a mark on it indicating the direction of rotation (7.9). Remove the timing belt, tensioner arm and pulley (7.41).

43. Unscrew bolts and remove sprockets of camshafts.

44 Remove the plug on the side of the cylinder block and block the shaft by inserting a screwdriver into the hole. Unscrew the oil pump sprocket nut and remove the sprocket.

7.45 DOHC engine rear timing marks

1. Silent shaft sprocket; 2. Stretched side; 3. Synchronization mark; 4. Rear crankshaft sprocket; 5. Synchronization mark

45. On a 4G32 DOHC engine, remove the rear belt. Make sure the timing marks are aligned correctly before removing the belt (7.45).

Examination

46. Rotate the tensioner pulley by hand and move it from side to side to check if the pulley is binding or if there is excessive play. Inspect sprockets for wear and damage. Replace if necessary.

47. Inspect the timing belt (7.20) for cracks, delamination, wear, missing teeth and oil contamination. Replace belts if necessary.

48. Inspect tensioner for leaks and obvious damage. Inspect the stem for wear and damage. Measure the protrusion of the rod, it should protrude 12 mm from the tensioner body.

49. Clamp the tensioner in a vise. Check stock condition. Replace tensioner if necessary.

Installation

50. Replace the sprockets if you removed them. Tighten the bolts to the required tightening torques.

Attention!

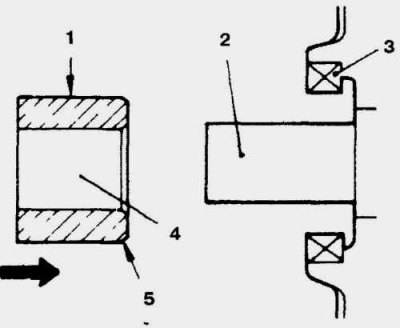

7.50 The cut edge of the sleeve must be directed inwards

1. Lubricate with oil; 2. Right silent shaft; 3. Oil seal; 4. Sleeve; 5. Cut edge

Make sure you correctly install the bushing on the crankshaft sprocket (7.50).

7.51 Check that the timing marks are aligned correctly.

1. Exhaust camshaft sprocket; 2. Holes for dowel pins; 3. Intake camshaft sprocket; 4. Surface machined cylinder head; 5. Synchronization marks; 6. Oil pump sprocket; 7. Crankshaft sprocket

51. Align the timing marks located on the sprockets of the camshaft, crankshaft and oil pump (7.51).

52. On 4G32 DOHC engines, install the timing belt. Install and adjust the rear belt, the deflection of the belt should be within 5.0-7.0mm.

53. Prepare the automatic tensioner for installation. If the tensioner rod protrudes completely, clamp the tensioner in a vise and slowly push the rod inward. Push in the stem until the hole in the stem lines up with the hole in the tensioner body. Insert a piece of wire into the holes to block the stem in this position.

54. Insert the automatic tensioner into place.

55. Install the tensioner pulley on the lever. Tighten the center bolt with your fingers, the two small holes in the pulley sleeve should be located on the left side of the center bolt.

56. Rotate the two crankshaft sprockets so that the dowel pins are at the top (7.51). Align the timing marks with the top surface of the cylinder head.

57. Align the timing marks of the crankshaft and oil pump sprockets with their corresponding marks on the cylinder block (7.51).

58. Remove the plug on the side of the cylinder block and insert a long screwdriver into the hole (7.16). If the screwdriver does not go deeper than 62 mm, this means that the marks are aligned correctly. If the screwdriver does not go deeper than 25 mm, then the oil pump sprocket needs to be adjusted.

59. Installing the timing belt:

- A. Pass the belt through the tensioner pulley and put it on the crankshaft sprocket.

- b. Put the belt on the oil pump sprocket.

- V. Put the belt on the intermediate pulley

- d. Put the belt on the intake camshaft sprocket.

- e. Rotate the exhaust camshaft sprocket one tooth to align the timing mark of the sprocket with the mark on the top surface of the cylinder head (7.51). Put the belt on the exhaust camshaft sprocket.

- e. Carefully lift the tensioner pulley and temporarily tighten the center bolt.

7.60 Use the special tool to apply the necessary force to the tensioner

60. Adjust the timing belt tension:

- A. Turn the crankshaft one fourth of a turn counterclockwise and then clockwise to set the N1 piston to top dead center.

- b. Loosen the center bolt of the tensioner and connect the special tool NMD998752 to the torque wrench (7.60).

- V. Tighten the center bolt to the required torque.

- d. Screw the NMD998738 special tool into the left engine bracket until the tip of the tool touches the tensioner arm. Continue to screw in the tool until the pressure on the auto-tensioner is relieved. Remove the wire that was inserted into the tensioner. Alternatively, you can press down on the tensioner pulley to compress the tensioner rod and then remove the wire.

- e. Unscrew the special tool.

- e. Rotate the crankshaft two full turns and wait 15 minutes. Measure how long the tensioner rod protrudes. The required value is 3.8-4.5 mm.

61. If the length of the protruding part of the rod does not fall within the required range, re-adjust the belt.

62. Install belt covers.

63. Replace the remaining parts.