2. Inspect the wires visually. In the dark, inspect the wires with the engine running, if there is a break in the wire, then sparks will be visible in this place.

3. High voltage wires must be checked one by one in order not to mix them up.

27.2 When disconnecting high voltage wires, grasp the cap, not the wires

4. Disconnect the wire from the spark plug (27.2).

5. Check the cap for corrosion and the tightness of its installation on the spark plug.

6. Wipe the entire length of the wire and check for cracks, burns, or other damage.

7. Disconnect a wire from the distributor. Check that the connection is secure and free from corrosion.

8. Check the other high voltage wires in the same way.

9. Replace wires if necessary.

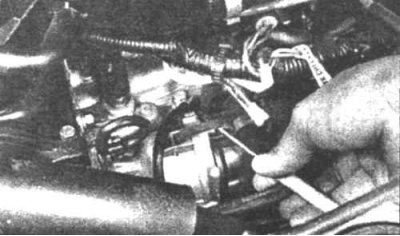

28.10a Using a small screwdriver, disconnect the distributor cap retaining clips

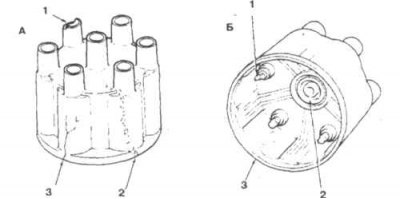

28.10b The main defects of the ignition distributor cover

A

1. Broken edge

2. Traces of sparks

3. Crack in the cover of the ignition distributor

B

1. Erased contacts

2. Worn or damaged coal

3. Traces of sparks

10. Remove the cover of the ignition distributor by disconnecting the two mounting clips (28.10a). Inspect the inner surface of the cover for cracks, traces of sparks, check the contacts (28.10b).

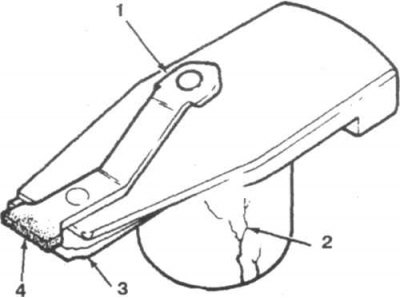

28.11 Check the ignition distributor for signs of wear or corrosion

1. Insufficient spring stiffness; 2. Cracks; 3. Traces of friction on the cover; 4. Corrosion at the tip of the slider

11. Remove the slider from the axle and inspect it for cracks and traces of sparks (28.11). Replace cap and slider if damaged.